Filter Case Studies By:

-

Characterizing and Monitoring Contaminants at a Complex Fractured Rock Site

Battelle has been working with the U.S. Navy for more than 15 years to characterize, treat and monitor groundwater at the former Naval Air Warfare Center (NAWC) Warminster. Groundwater in fractured rock beneath the site is contaminated with chlorinated volatile organic compounds (CVOCs) from historic activities at the site.

-

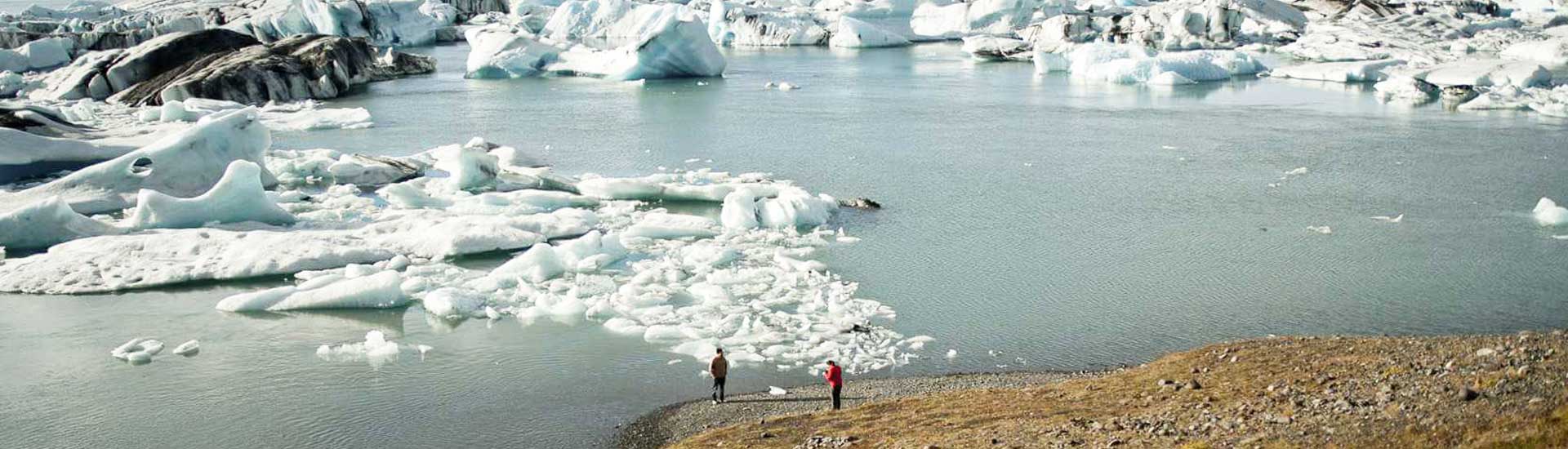

Providing Training to USAID Staff on Global Climate Change

Climate change is already having impacts on human health, infrastructure, ecosystems and security worldwide, serving as a threat or risk “magnifier” that compounds existing challenges in multiple sectors. As a key member of a team supporting USAID, Battelle staff helped pioneer the development and delivery of a climate change training course to USAID staff worldwide.

-

Optimizing Industrial Hygiene Practices for the U.S. Air Force

The U.S. Air Force came to Battelle for help in developing coaching programs that would prepare base personnel to implement an effective industrial hygiene program using the Defense Occupational and Environmental Health Readiness Systems. See the results of our work.

-

Characterizing Food Additives to Determine Statistical Equivalence

A food manufacturer came to Battelle for help in proving statistical equivalence of their new food product formulation for regulatory purposes. The manufacturer was phasing out an ingredient due to consumer concern and the potential for future regulation. In order to reduce the likelihood that they would need to conduct expensive regulatory studies and resubmit the product for FDA approval, the manufacturer needed to be able to prove that the new product was substantially equivalent to the old product with the exception of the removed ingredient.

-

Producing Fuel Blending Components from a Fischer-Tropsch Wax

Battelle and the University of Dayton Research Institute produced small lots of SPK from commercially available Fischer-Tropsch wax to allow researchers in the Air Force Research Laboratory (AFRL) to examine how variations in the SPK could affect aircraft performance.

-

Developing a Fast-dispersing Extruded Water-dispersible Granule

A research-based agrochemical producer came to us with an apparently simple challenge: developing an extruded granule that dispersed as fast as spray-dried water-dispersible granules (WGs). After studying and testing a number of substitutes, the team discovered the most suitable new filler and surfactant combination—one that resulted in an extruded granule with a rapid rate of dispersion, both initially and after storage.