Granular Activated Carbon Regeneration Technology

A New Method for

an Old Problem

Battelle has pioneered a method of reactivating GAC on-site–eliminating the need to ship it back to the vendor. This innovative approach to GAC regeneration reduces operating costs and lengthens the life of the system. This is environmental science that saves time, money, and energy.

Exclusive Technology Services. Total PFAS Destruction.

Battelle is dedicated to applied research and development and technology optimization in environmental investigation and remediation. We are launching Revive Environmental to deploy PFAS Annihilator™ and GAC Renew™ at scale for maximum impact.

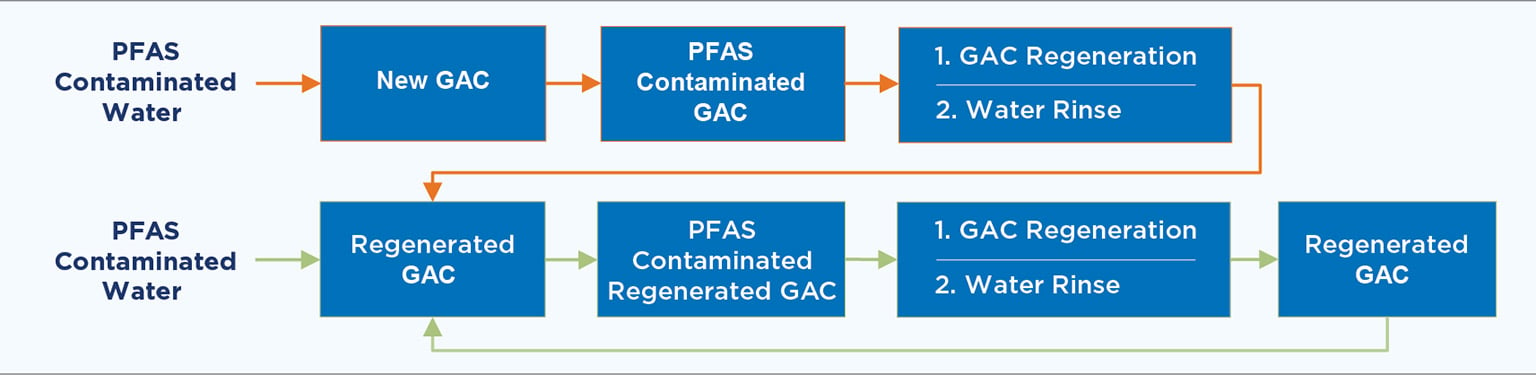

How It Works

Battelle’s solvent-based technology for on-site GAC regeneration includes at least two tanks of GAC. One tank is taken offline while the second tank allows GAC treatment to continue uninhibited during regeneration. The regenerant solution is stored on site and is cycled through the tank for the number of bed volumes (determined during laboratory column studies) that best regenerate the GAC. The spent regenerant solution is distilled for recycling. After the solution has regenerated the spent GAC, potable water is passed through that tank to rinse the GAC before putting it back online.

Features of Our GAC RENEW™ Technology

- Can effectively reactivate GAC using solvent-based technology

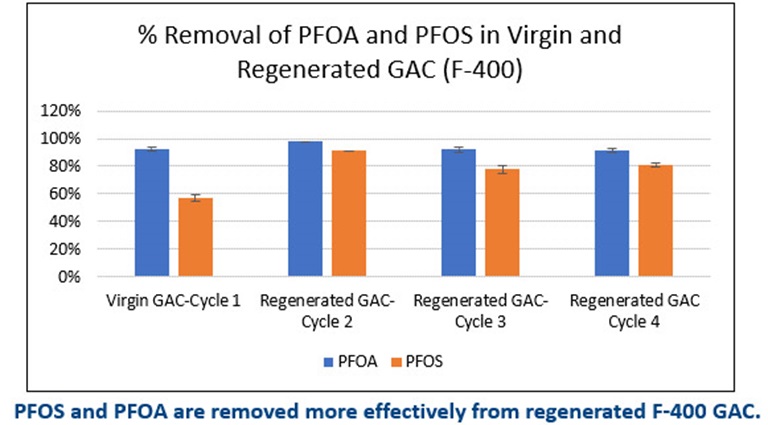

- Better PFAS removal is obtained from the solvent-regenerated GAC than virgin GAC, even after four solvent-regeneration cycles

- Spent regeneration solution can be distilled for recycling and the concentrated distillate treated on site with Battelle’s PFAS ANNIHILATOR™ Destruction Technology

Granular Activated Carbon Regeneration Technology Case Study

Related Product and Service Solutions

-

service

service

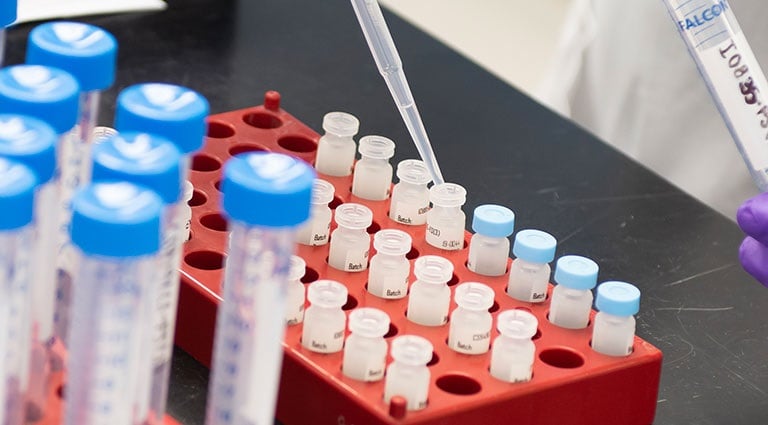

Accredited PFAS Laboratory

Providing high-quality, defensible data with very low limits, as well as new method development and optimization. -

service

service

PFAS SIGNATURE® Advanced Analytics Tool

Understanding the specific signatures of PFAS analytes in different matrices to deduce information about their sources. -

service

service

PFAS PREDICT™ Groundwater Fate & Transport Modeling

Simulates PFAS fate and transport with unique options to scale dispersion processes based on modeling PFAS groundwater plumes. -

service

service

PFAS Insight® Passive Sampling Technology

Overcomes the challenges of legacy samplers to specifically work for the large variety of PFAS contaminants. -

service

service

PFAS AIR INSIGHT™ Technology

Measures PFAS in ambient air to better understand potential exposures and possible human and environmental health risks. -

product

product

PFAS ANNIHILATOR™ Destruction Technology

Destroys PFAS and prevents them from transferring elsewhere, while not creating harmful byproducts.

Featured Experts

-

Dinusha Siriwardena, Ph.D.

Research ScientistDinusha is working on various remediation technologies for PFAS and has significant experience in experimental design and implementation in groundwater remediation, wastewater treatment and energy/sustainability projects. -

Ryan James, Ph.D.

Senior Research ScientistRyan has a Ph.D. in analytical chemistry, which he has applied to various studies on drinking water system decontamination research, drinking water treatment, technology testing, field sampling, analytical methods development and lab analysis of environmental and biological samples.

-

Kavitha Dasu, Ph.D.

ChemistKavitha leads innovative analytical research in per and polyfluoroalkyl substances (PFAS) to solve highly complex environmental problems, including new method development efforts.