Hardware and Systems Assurance Solutions

A Serious Challenge to our Nation’s Supply Chain

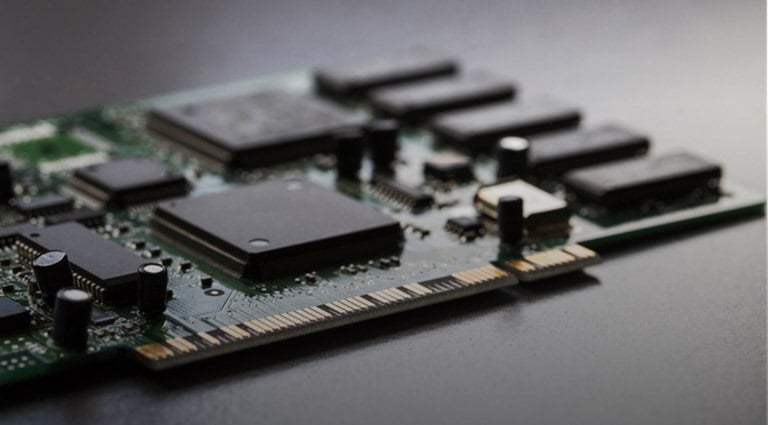

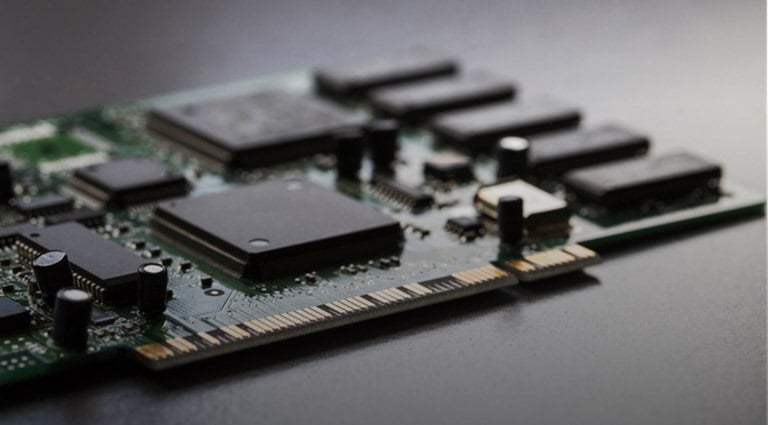

Productive hardware security and software security require that commercial-off-the-shelf (COTS) components and printed circuit boards (PCBs) remain uncompromised. We develop and implement revolutionary microelectronics inspection and security assessments that enhance the safety of the nation’s military, as well as civilian critical assets.

Through cyber-physical analysis and data analytics that incorporate AI/ML algorithms, we deliver effective, adaptable, and practical detection and monitoring solutions that quickly find threats, mitigate them and stop others from breaching your architecture.

The Battelle Embedded System Assurance

Eco-System

We ensure microelectronics supply chain security through automated, non-destructive hardware and software solutions that quantify the trust and assurance of COTS PCB assemblies.

Battelle applies tools and expertise to quantify risk throughout the entire platform life cycle for safe introductions of commercially sourced chips, embedded cyber programs and more. We offer the following assurance and monitoring solutions:

Design Phase |

|

Production Phase |

|

Operations and Maintenance |

|

| Ready-to-Use Technologies |

|

Our End Products and Services Built to Secure Microelectronics

-

service

service

Custom Hardware Assurance Services

Authenticate all integrated circuits; eliminate counterfeit or clone devices throughout systems, infrastructure and devices. -

product

product

Barricade™ Circuit Verification Technology

Authenticate all integrated circuits; eliminate counterfeit or clone devices throughout systems, infrastructure and devices. -

product

product

Rapid Assembly Inspection for COTS Security (RAICS)

RAICS analyzes PCB assemblies, quickly assess COTS devices, and receives multimodal image set generation in a single hardware unit solution. -

service

service

Test and Evaluation

Battelle experts help to examine and thoroughly inspect microelectronics to detect vulnerabilities and counterfeit chips through every step of the process.

-

“Today's weapon systems are heavily computerized, which opens more attack opportunities for adversaries.”

Government Accountability Organization Report to U.S. Senate Armed Services Committee

Microelectronics Assurance Laboratory

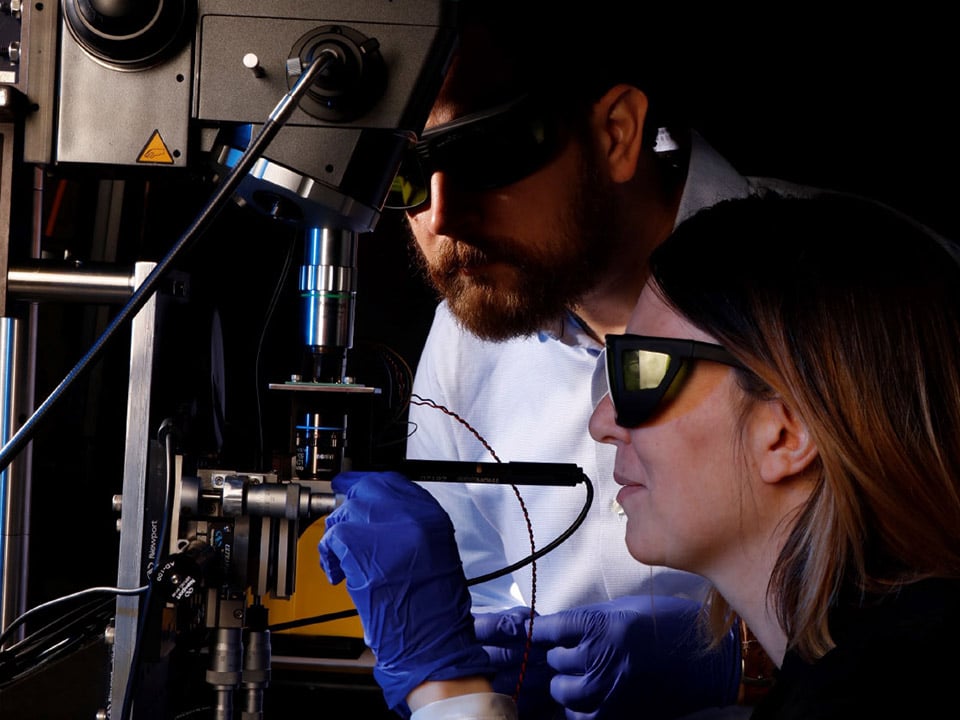

Battelle's microelectronic security lab houses specialized tools and equipment for destructive and nondestructive device and subsystem characterization, including:

- RAICS technology integrated circuit boards

- Barricade™ technology nondestructive counterfeit detection

- Scanning optical (SOM) and electron (SEM) microscopy

- Focused ion beam (FIB) imaging

- Sample preparation

- Probe station with laser circuit editing

- Wire-bonding

- Physical and chemical de-packaging equipment

Featured Experts

-

Adam Kimura, Ph.D

Design Verification LeadAdam, our Design Verification Lead, guides major microelectronics verification and validation efforts as a principal investigator for Battelle’s clients.

Related Solutions

-

solution

solution

Cyber Mission-Focused Tools

Battelle helps government clients gain rapid tactical advantage with cyber solutions that combine hardware and software vulnerability research, reverse engineering capabilities, and radio-frequency engineering. Our expertise ensures operator success on the electronic battlefield across all domains.

-

solution

solution

Cyber Solutions

Battelle provides solutions and services to meet urgent and complex cyber technology challenges. Through our tailored intel solutions, architecture and advisory services, and platform solutions, we help defend national security and commercial interests against ever-changing cyber threats. -

product

product

Rapid Assembly Inspection for COTS Security (RAICS)

RAICS analyzes PCB assemblies, quickly assess COTS devices, and receives multimodal image set generation in a single hardware unit solution. -

product

product

Barricade™ Circuit Verification Technology

Authenticate all integrated circuits; eliminate counterfeit or clone devices throughout systems, infrastructure and devices.

Join the Battelle Cyber Team

Technology Commercialization and Licensing

With over 90 years of research and development experience, Battelle supports all areas of industry with intellectual property focused on supply chain assurance including non-destructive, rapid inspection technologies, and full range of risk mitigation solutions.