Rapid Assembly Inspection for COTS Security (RAICS)

Microelectronics Inspection Tool to Ensure Hardware Security

Many mission-critical systems rely on commercial off-the-shelf (COTS) components and printed circuit boards (PCBs). In order to meet emerging zero-trust requirements, there will be a need to inspect all existing and incoming hardware.

PCBs host COTS devices from hundreds of authorized and non-authorized distributors worldwide. This creates a risk for tampering, modification, or counterfeit elements before installation into critical assets.

RAICS is the first automated, non-destructive , hardware and software solution to quantify the trust and assurance of COTS PCB assemblies and enable direct integration of the PCB supply chain into locations such as PCB manufacturing facilities, repair depots, and test and integration facilities.

Download our free RAICS one-page information brief

How It Works

RAICS utilizes a data-driven test approach to quantify the risk of PCB assemblies, enables a direct integration into logistics depots and platform assembly locations, and supports the needs of emerging zero-trust supply chain requirements.

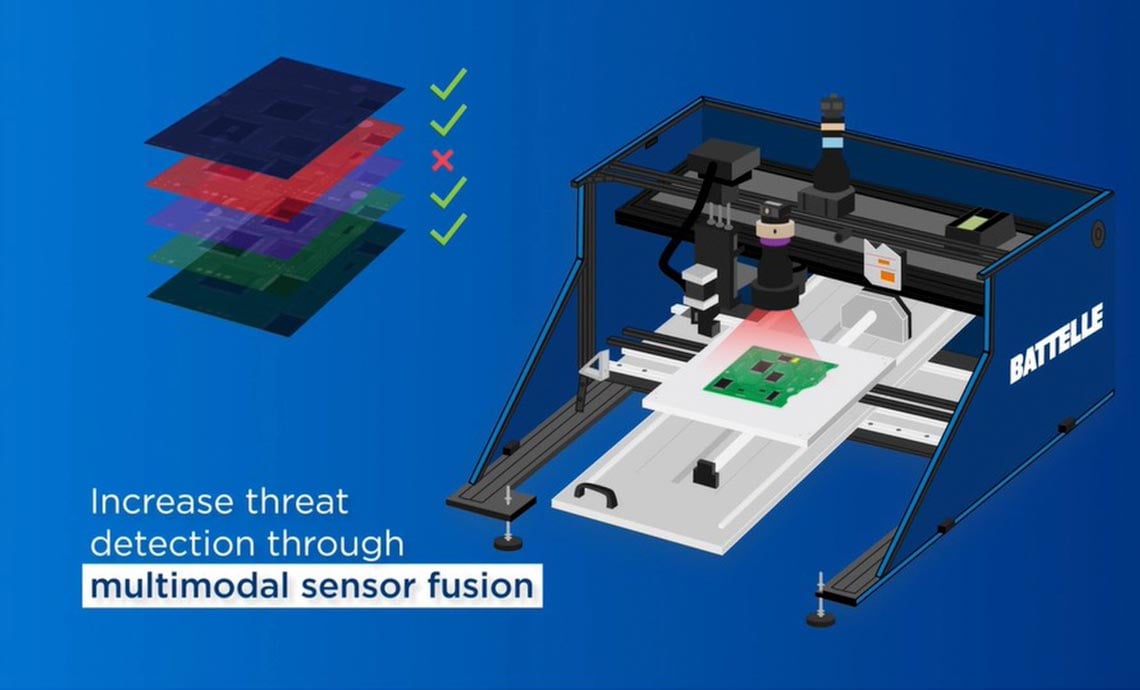

Battelle RAICS tests and verifies COTS boards and applies sensor fusion to a myriad of sensing modalities to create a unique multimodal signature of a PCB assembly. This signature includes the individual components, architectural relationships, manufacturer markings and other identifying characteristics.

The digital signature enables the identification of a compromised or anomalous device among its duplicates. By comparing the signature to a database of known device components, we can identify probable anomalies and counterfeit boards and components, even in the absence of a 'golden reference’ sample for comparison. Design files are not required for RAICS to be effective.

Reduce time and cost in your supply chain security inspections and verification.

As an integrated hardware and software solution, RAICS is designed specifically to assess PCB trust and assurance, minimize the search space for threats, reduce the inspection time from hours to minutes, and standardize the risk reporting process with bill-of-material (BOM) generation and quantified anomaly assessments.

Join the Battelle Cyber Team

Related Products and Services

CANprotect™: Anomaly Detection for Cyber-Physical Networks

Barricade: Identify Counterfeit Hardware and Integrated Circuits

Featured Expert

-

Anthony George

Cyber Principal Investigator and Lead ResearcherAnthony is the lead researcher in the Cyber Trust and Analytics business line and the principal investigator for the Battelle RAICS technology. He received his B.S. in electrical engineering from Ohio University and an M.S. in electrical engineering at the University of Tokyo in Japan. Anthony is an expert in computer vision and non-destructive inspection techniques with six journal publications and five patents internationally.

Technology Commercialization and Licensing

With over 90 years of research and development experience, Battelle supports all areas of industry with intellectual property licensing focused on non-destructive rapid inspection technologies, mitigation solutions, and technological innovation to ensure microelectronics supply chain assurance.